OLIVER MODELL 600

Characteristics of the OLIVER MODEL 600

- 700 kg base guarantees vibration-free work with positive grinding results

- Perfect finish thanks to short and rigid tool mount even at heaving in-feed

- Typical Oliver-point with increasing clearance angle from circumference to the chisel edge withe extension option independent of the position of the chisel edge

- The chisel edge produced is highly self-centring, permits high in-feeds simultaneous with low cutting forces

- Low blade stroke produces bores with tight tolerances

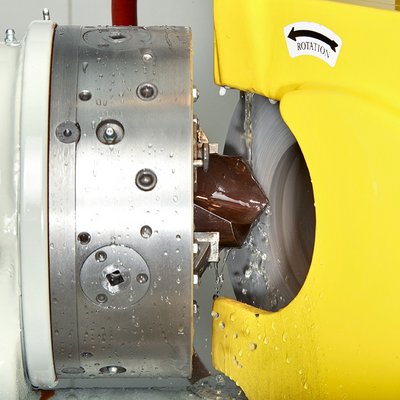

The typical Oliver-point has an increasing clearance angle from the circumference to the chisel edge that can be modified independently of the position of the chisel edge. The chisel edge created is highly self-centring and permits high in-feeds simultaneous with low cutting forces. A low blade stroke produces bores with tight tolerances.

Equipment

Equipment for the spiral drill grinder OLIVER MODELL 600

- 9" x 2" x 5"-grinding disc steel backing, a diamond truing tool and a clamping chuck key

- Water-tight halogen work lamp

- Separate tank and motor pump with splash protector and pipes for cooling the grinding range

- Automatic in-feed system (connection to compressed air system with 60 lbs. pressure required)

- Open ball-bearing motor: 2 PS, 380 Volt, three-phase, 50 Hz

- Allen-Bradley IEC-motor starter combination type 3/4/12 circuit breaker and transformer

- Metric in-feed scale (No. 6312)

- Allen screws for clamping chuck jaws

- Allen wrench set for removing the Allen screws

Technical Data

- Point angle

80° - 160° - Tool types

- Spiral drill, spiral countersink, 2, 3, 4 Blades, clockwise cutting

- Tool mount

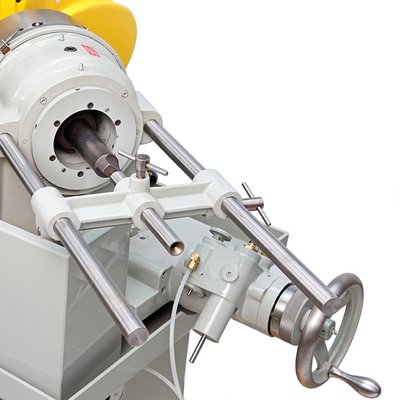

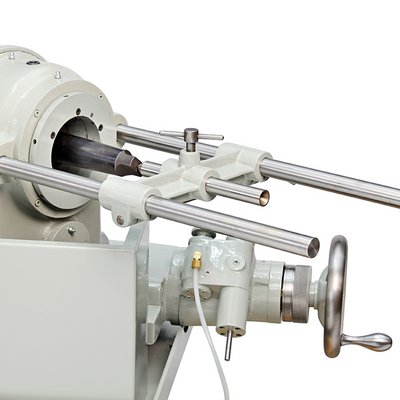

Stable, adjustable precision-clamping chuck clamping prisms - Counter holder

With 2 double guide shafts and centring point for exact tool concentricity - Grinding range

13,0 - 76,0 mm (optional 13,0 - 100,0 mm) - Max. tool length

710 mm - Grinding disc

9´´ x 2´´ x 5´´ (228,6 x 50,8 x 127 mm) - In-feed

0,010´´/min (0,25 mm/min)

0,10´´/min (2,54 mm/min) - hydro-pneumatic

air connection of 6 bar required - Electrical equipment

1,5 kw - 380 V - 50 Hz - 3/N/Pe - Coolant pump

- Power

0,25 kW - Connection

380 V - 50 Hz - Coolant

ca. 30 l

- Power

- Dimensions (WxHxL)

1.4 x 1.7 x 1 m - Weight

700 kg

Videos

Drill sharpeners always in stock, with plenty of service

Brinkmann + Wecker is the exclusive importer for DAREX drill sharpeners and Oliver of Adrian drill point thinners.

Your benefit: All sharpening machines and replacement parts are always in stock.

In a video chat, our experts will be happy to give you a live demo showing how to use our machines.

Try it now!